Efficiency Important in Preparing Tobacco for Market

Efficiency Important in Preparing Tobacco for Market

Across Kentucky, tobacco stripping rooms are filled with workers removing the leaf from the stalk and placing it into bales. By operating this system as efficiently as possible, farmers can keep expenses under control.

Farmers also need to divide the leaf into the grades specified by the tobacco company with whom they have a contract. This is important in order to attain the best prices for their leaf. Properly preparing the crop for market is an important step and one that can be costly if not done with quality and efficiency in mind.

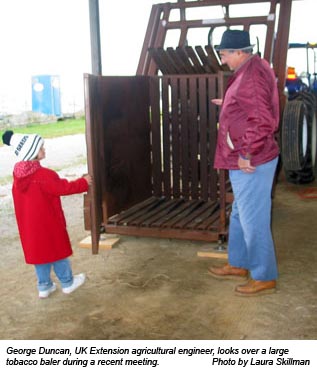

During a recent tobacco meeting in Breckinridge County, stripping and baling were two of the main topics of discussion. Part of that discussion centered on stripping room redesign or construction as farmers move from 80-pound to 600-pound tobacco bales.

Packaging tobacco for market has evolved throughout the years with most producers today baling their leaf into square bales weighing between 80 and 90 pounds. However, larger bales are beginning to be seen on more farms and are being encouraged by some manufacturers. These large balers require more space not only for the machine but also for containers to store the leaf in until enough has been accumulated to make a bale.

The large bales can be more efficient, said George Duncan, Extension agricultural engineer with the University of Kentucky College of Agriculture.

“On the UK farm last year, where the farm manager kept accurate daily records, going from small bales to large bales resulted in a 19.2 percent increase in productivity,” he said. “Other people tell me they have seen an increase in productivity of 50 percent. That’s probably on the upper end.”

But if producers aren’t using an efficient process where they do not have to handle the leaf multiple times, then the large bales will not improve productivity and could hurt it.

“Big balers have brought on changes in the stripping room,” Duncan said. “The one thing that is a principle in trying to adapt the big baler and make it work efficiently, is a minimum amount of time you handle the leaf from the time you take it off the stalk until it’s in the bale and how many people you have.”

Stripping rooms may need to be adapted to accommodate changing from small to large bales to maintain efficiency. This may include space for more storage bins, larger doors for efficient movement of the bins and wagons, easy access to the baler and quick stalk removal. UK has a number of stripping room redesign and new design ideas for farmers that should fit almost any situation. Local county offices of the UK Cooperative Extension Service can assist farmers with these designs.

Duncan also noted that as farmers move from small to large bales, they need to investigate the different types of balers available. Some have a single door while others have a two-door system, and the hydraulic press does not operate the same in all models. He also noted that it is worth the additional cost to include weigh scales on the baler to ensure consistent bales.

While improved efficiency and more rapid handling are possible, there is a significant investment required for a big baler, he said. The lower cost balers can use tractor hydraulic power, which requires the operation of a tractor to make a bale, whereas the more costly balers have a 230-volt electric powered hydraulic system. Prices range from $5,500 to $8,500 for various models. Some cost sharing is available from various sources.