UK students creating safer PPE for frontline workers

UK students creating safer PPE for frontline workers

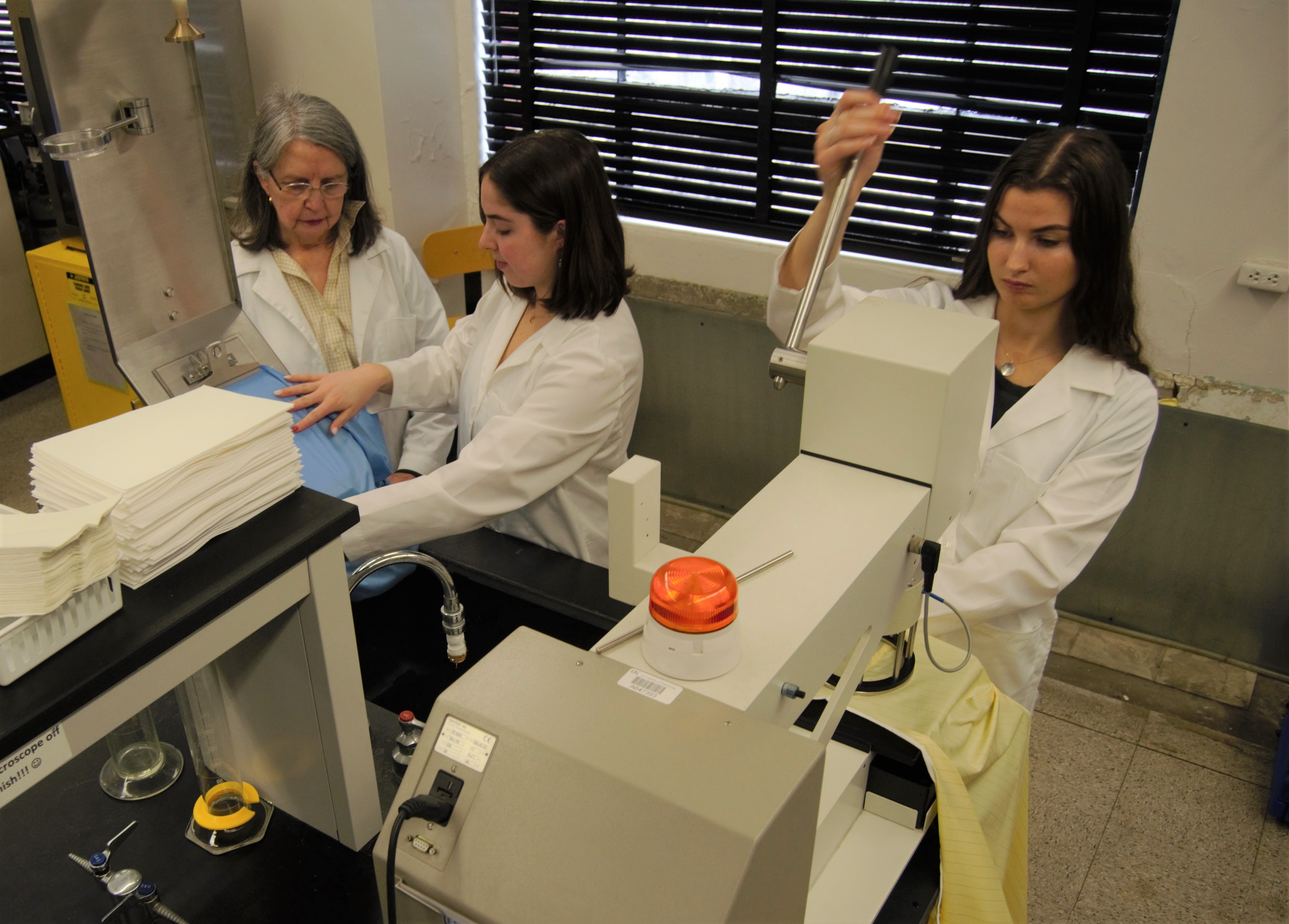

University of Kentucky students in the Textile Testing laboratory are helping develop durable, reusable PPE for health care workers.

The UK College of Agriculture, Food and Environment houses the lab, which specializes in testing fabrics and materials for the textile industry to make sure they stand up to proper safety protocols and industry standards. One of the most critical responsibilities is the personal protective equipment (PPE) health care workers use in their daily jobs.

“We’ve tested PPE for years,” said Elizabeth Easter, UK professor in the Department of Retailing and Tourism Management who heads the lab. “However, since the COVID-19 pandemic, we have increased PPE testing and now test for both suppliers and the health care workers who use it. At the same time, our students are getting real-world experience.”

UK’s primary PPE testing involves apparel such as isolation and medical gowns.

"Isolation gowns are vital in protecting the health care worker from COVID-19," Easter said. "We test the durability of reusable gowns. Before the pandemic, the majority of all isolation gowns were disposable."

Thanks to the testing lab, health care workers can use at least five different types of gowns for up to 75 wash cycles. However, the lab doesn't stop there. Students test everything from lab coats to firefighting PPE.

"We have years of experience working with firefighters and general workwear, which you might find at a car plant or package delivery company," Easter said.

Since 1988, the UK Textile Testing Lab has received continuous funding from the Association for Linen Management (ALM), a group dedicated to the professional development of personnel in the textile care industry. The lab helps provide the ALM’s members with a test-piece service, a quality control tool that enables linen managers to monitor their ability to maintain aesthetically pleasing and durable textiles.

Student lab technicians prepare and evaluate the test piece then measure the tensile strength of the test piece to determine the durability and the whiteness index for aesthetics.

UK's lab provides research and laboratory technician experience to these students who work as paid technicians under the direction of the laboratory supervisor and Easter. The lab also provides funding for graduate student research assistants and the opportunity for students to conduct thesis research projects within the industry who gain experience in solving real-word problems.

Former UK student Susan Dabbain was a technician who gives credit to the Textile Testing Lab for her future.

“At the time, I had no clue what I wanted to do as a career, and my major required me to have an internship before I graduate,” said Dabbain, now a lab assistant at Kinectrics, a company that provides testing, inspection, certification and engineering consulting for the electric power industry. “I wanted to be able to make some difference in my work, and my experience in retail did not satisfy that. I took one of Dr. Easter's classes and applied for an internship to work in the lab. This experience opened a whole new world for me, a world I did not think existed."

After her internship, Dabbain returned to UK to obtain her master's degree. When COVID-19 struck the nation, she realized that there was more to textiles than just fashion.

“Textiles is also about protecting the lives of those caring for and protecting our lives,” she said. "The main issue during the pandemic was lack of PPE supplies since most supplies are disposable. There was a limited market for reusable PPE, and research on reusable PPE was almost nonexistent. This is where I thought I could make a difference in my work, so I decided to take the deep dive into researching and evaluating reusable PPE over periods of laundering."

While studying for her master’s degree, Dabbain tested PPE samples’ liquid-barrier properties, comparing data and writing a thesis.

Dabbain said that thanks to her time working in the testing lab, she was able to land on a career path full of opportunity that allows her to keep people safe. She now works testing flame-resistant and arc-rated PPE, including fall protection, arc flash, and flame-resistant clothing, blankets, face protection and gloves. Arc rated means that the clothing material has been tested for exposure to an electrical arc and given a value according to its performance.

"I fell in love with this part of the industry, especially quality control and PPE," Dabbain said. "Having spent so much time in our little university laboratory, I could dip my toes into this industry and come into my career feeling prepared. I am extremely grateful for getting to learn so much and apply it in my career now."

Retailing & Tourism Management Students